Straight Light Pole Specifications for Street Lighting

When you design a modern lighting layout, a straight light pole often serves as the most reliable and consistent choice. These poles maintain a uniform diameter from the base to the top, making them a staple in urban infrastructure and residential streetscapes. The simplicity of the design means that getting the pole specifications right is the only way to ensure the system survives the physical demands of the outdoors. You must look beyond the visual profile and focus on the technical details that dictate how the pole handles the weight of the fixture and the force of the elements.

Specifications act as the blueprint for the long-term success of your project. If you overlook the load capacity or the quality of the finish, you risk premature rusting, sagging, or total structural failure. You must adhere to strict installation standards to ensure every pole remains perfectly vertical and secure over its entire service life. By understanding the relationship between the physical attributes of the pole and its real-world performance, you can select hardware that provides steady, safe illumination for decades. This approach moves you away from guesswork and toward a data-driven strategy that prioritizes reliability and public safety.

What defines a straight light pole and why it’s used in street lighting

A straight light pole is defined by its constant cross-section. Unlike tapered poles that narrow at the top, a straight pole maintains the same width from the base to the fixture mounting point. This pole design is highly valued for its clean, vertical lines, which help it blend into park settings, shopping districts, and low-speed residential roads. It is often the preferred choice when you want a uniform look across a large development, providing a balanced visual rhythm that does not distract from the surrounding architecture.

In the world of street lighting, these poles offer a practical solution for mounting fixtures at heights typically ranging from 10 to 25 feet. While they are functionally simpler than their tapered counterparts, they provide the necessary stability for standard LED fixtures. Their predictable shape makes them easier to manufacture and often more cost-effective for large-scale municipal projects. When you integrate straight poles into your city lighting plan, you are choosing a versatile tool that supports both the functional needs of drivers and the aesthetic goals of the community.

Which technical specifications matter most for straight light poles

The most critical factor for any straight pole is its load-bearing capacity, which is a combination of the wall thickness and yield strength of the material. You need to ensure the pole can support the “dead weight” of the light fixture and the arm without bending. Beyond raw strength, specification standards usually dictate the type of finish—such as hot-dip galvanization or powder coating—that protects the metal from oxidation. This durability is what prevents a pole from becoming a structural liability within just a few years of exposure to rain and humidity.

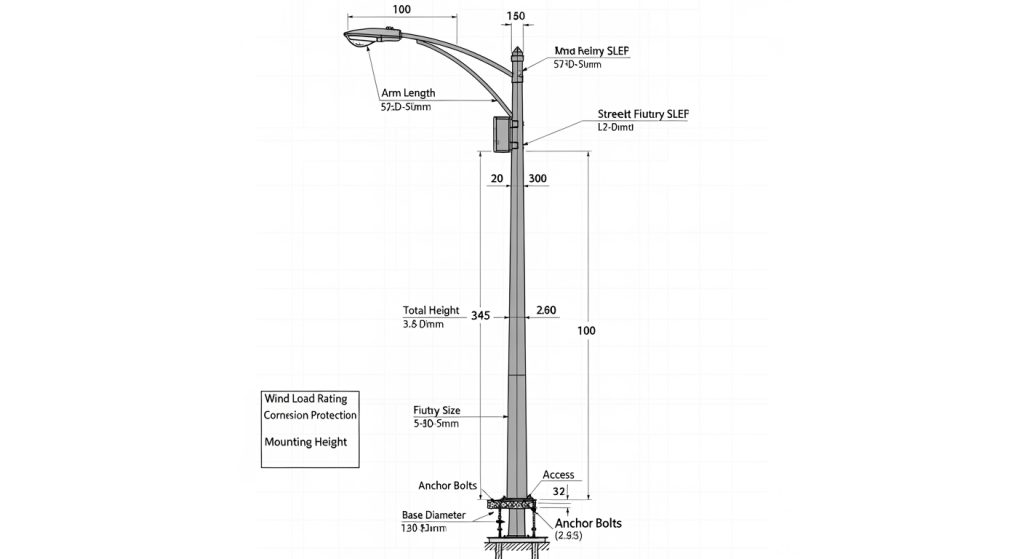

You also need to verify the anchor bolt specifications and the base plate thickness. These components are responsible for transferring all the physical stress from the pole down to the concrete foundation. If the base plate is too thin or the bolts are not high-tensile grade, the pole may develop a lean or rattle in the wind. By focusing on these hidden technical details, you ensure the pole has the internal strength to stay upright. A well-specified straight pole does not just look good; it acts as a permanent, rigid anchor for your lighting system.

Why height and reach are critical for straight pole performance

The pole height you select is the primary lever you have for controlling light distribution across the road. For straight poles, maintaining a specific height is vital because it determines how much area a single fixture can cover. If your pole is too short, the light will be concentrated in a small circle, creating harsh shadows and poor visibility for drivers. Increasing the height allows the beam to spread wider, which helps you achieve a more uniform glow and improves visual comfort for everyone on the road.

You also have to consider the “reach” or the arm length attached to the straight pole. Because these poles are often set back from the curb to prevent car strikes, the arm must extend far enough to place the light directly over the driving lanes. If the height and reach are mismatched, you end up with wasted light on the sidewalk and a dark, dangerous road surface. When you get the geometry right, you maximize the performance of your lamps and ensure the light is placed exactly where it will help prevent accidents.

How environmental conditions affect straight pole specifications

Every straight pole must be built to handle environmental stress, with wind resistance being the most significant factor. Because a straight pole does not have the natural aerodynamic advantages of a tapered design, it can catch more wind, especially if it is carrying a large fixture. Your specifications must account for the peak wind gusts in your specific region to ensure the pole does not suffer from metal fatigue or snap during a storm. This is a non-negotiable part of maintaining long-term stability.

In addition to wind, you must account for local climate challenges like salt air in coastal regions or heavy snow loads in colder areas. In seismic zones, the pole must have enough flexibility to absorb vibrations without cracking at the base. These factors change the material requirements, often forcing planners to choose thicker walls or specialized alloys. By matching the pole specifications to the local weather and geography, you prevent the environment from slowly destroying your infrastructure, ensuring the poles remain safe for the public.

What installation factors planners must include in pole specification decisions

Successful installation planning starts with a deep understanding of the ground stability at your site. A straight pole is essentially a long lever, and the force it exerts on the ground is immense. You must specify a foundation design that matches the soil type; for example, loose sandy soil requires a much larger concrete base than dense clay. If the foundation is not matched to the height of the pole and the resistance of the soil, the entire unit can shift or sink over time.

Planners also need to consider the precision of the alignment during the pour. If the anchor bolts are even slightly crooked, the straight pole will accentuate that lean, making the installation look unprofessional and potentially compromising the aiming angle of the light. You should include specifications for conduit placement within the foundation to ensure power cables can reach the fixture without being pinched or exposed to moisture. A solid, well-leveled base is the only way to guarantee your poles stay straight and functional for their intended life.

How maintenance and service life influence specifications

When you look at maintenance planning, you realize a pole service life is largely determined by how easy it is to keep in good repair. For straight poles, specifications should include accessible hand-holes with secure covers, allowing technicians to reach the wiring without specialized tools. You want to choose materials and finishes that reduce the need for frequent repainting or rust treatment. This focus on cost-effectiveness ensures the initial investment pays off over decades rather than years.

A pole that is built to high specifications will resist the wear and tear of urban life, from minor bumps to chemical exposure from road salt. If you choose a lower-grade specification to save money upfront, you will likely spend more on repairs and early replacements. By specifying high-quality, corrosion-resistant hardware from the start, you protect the municipality or developer from the rising costs of labor and materials, ensuring the lighting system remains an asset rather than a burden.

What mistakes reduce the effectiveness of straight pole installations

One of the most common planning mistakes is a design mismatch, where a standard straight pole is used in an area with extreme wind conditions without increasing the wall thickness. Another frequent error is assuming a foundation designed for a 15-foot pole will work for a 25-foot pole. These performance gaps often lead to poles that sway excessively, which not only looks dangerous but can also damage the sensitive electronic drivers inside modern LED fixtures.

You must also avoid neglecting the anchoring hardware. Using standard bolts instead of the specific high-tensile fasteners required by the manufacturer can lead to failure during high-wind events. Planners sometimes fail to account for the total “wind sail” area of the arm and the fixture combined, leading to a pole that is structurally overloaded. By double-checking every calculation and ensuring the pole is rated for the specific accessories you plan to attach, you can avoid these costly and dangerous blunders.

What checks should planners complete before finalizing straight pole specifications

Before moving to the procurement phase, a final specification validation is necessary to ensure all technical requirements align with the project goals. You need to verify the chosen height, material, and foundation are all compatible with the specific environmental and road conditions of your site. This design checklist acts as your final safeguard against installation errors and premature failure, ensuring implementation readiness.

Use these points to finalize your straight pole plan:

- Confirm the pole height matches the required light spread for the road width.

- Verify the wind load rating accounts for both the arm and the fixture.

- Check that the material finish is appropriate for the local climate.

- Ensure the foundation design is calculated based on a recent soil report.

- Validate that anchor bolts and base plates meet the required tension and thickness standards.

- Review the internal wiring space and hand-hole locations for ease of maintenance.

- Check for compliance with local municipal or DOT installation standards.

What specifications should street light poles and brackets meet

When selecting Street light poles brackets, you must ensure they adhere to international pole standards. This means the mounting hardware and the pole itself must have a verified bracket compatibility so the fixture does not vibrate loose. The specifications should cover the bolt pattern of the bracket and the diameter of the tenon to ensure a watertight fit that protects the electrical components from the elements.

How should planners determine the correct pole height for street lighting coverage

An effective Street light pole height guide relies on a balance between the lumens of the lamp and the desired light distribution. In pole height planning, you must calculate how high the light needs to be to reach the center of the road while still maintaining enough intensity to see clearly. Taller poles allow for wider spacing between units, which can reduce the total number of poles needed, but they also require stronger foundations to be effective.

How do aluminum and steel street light poles compare for specifications

An Aluminum vs steel light poles material comparison is essential for meeting project specs. Steel is the leader in strength vs weight, making it the best choice for very tall poles or high-wind areas. However, aluminum is naturally resistant to corrosion, which often makes it the specified choice for coastal projects where salt air would destroy steel. Your choice should depend on whether you prioritize the raw structural power of steel or the low-maintenance longevity of aluminum.

What does a tapered light pole design contribute to specification needs

The Tapered light pole explained highlights a major step in structural efficiency. A tapered design moves the center of gravity lower and reduces the wind profile at the top of the pole, which often allows for thinner wall specifications than a straight pole of the same height. This geometry makes the pole more resilient to the constant shaking caused by traffic and wind, making it a common specification for highways and high-exposure bridges.

Why is foundation design essential for straight street light poles

According to Street light pole foundation principles, the foundation design is the only thing providing ground support for the leverage of the pole. For straight poles, the base must be deep enough to resist the overturning force during a storm. A properly specified foundation ensures the pole remains a permanent part of the landscape rather than a temporary fixture that leans or fails as the soil settles or shifts over the years.

Final Thought

Getting straight light pole specifications right is a balance between understanding physical forces and meeting community needs. When you prioritize material quality, correct height, and environmental resistance, you create a lighting system that is as durable as it is effective. By following these technical standards, you ensure the streets remain safe, well-lit, and easy to maintain for decades to come.

- 10 Meters Lamp Post

- 10 Meters Pole

- 1000w Led Projector

- 100W LED Tunnel Light

- 12 Meters Lamp Post

- 12 Meters Pole

- 1200w Led Projector

- 15 Light Pole

- 1500w Led Projector

- 150W LED Tunnel Light

- 1800w Led Projector

- 2 In 1 Solar Flood Light

- 200w Led Tunnel Light

- 50w Led Tunnel Light

- 6 Meters Lamp Post

- 6 Meters Pole

- 8 Meters Lamp Post

- 8 Meters Pole

- 800w Led Projector

- 80w Led Tunnel Light

- Colourful Decorative Light

- Conical post

- Courtyard Lamp

- courtyard light

- courtyard lighting fixture

- Decorative Landscape Light

- Decorative road Light

- Flood Light For Courtyard

- Flood Light for Garden

- Flood Light For Outdoor

- Foot Led High Bay Lights

- high bay led lights 100w

- industrial lampshade

- industrial LED shed lights

- industrial magnifying glass with light

- Integrated Solar Flood Light

- led courtyard lamp

- led courtyard light

- led high bay light 100w

- LED Projector For Stadium

- Led UFO High Bay 150W 5000k

- Lighting Plants Mining Price

- Maintenance Free LED Street Light

- Pic Controlling Tunnel Light

- PLC controlling tunnel light

- Post Top Garden Light

- RGB Landscape Light

- Rgbw Decorative Light

- Smart Tunnel Light

- solar courtyard lamp

- solar courtyard light

- Solar LED Road Light

- Solar Street Light For 10 Meter Pole

- Solar Street Light For 12 Meter Pole

- Solar Street Light For 6 Meter Pole

- Solar Street Light For 8 Meter Pole

- Split Type Solar Flood Light

- Sporting Projector

- Stadium Led Projector

- Street Lighting Post

FACEBOOK

FACEBOOK

TWITTER

TWITTER

LINKEDIN

LINKEDIN