Street Light Poles Arms and Brackets Guide

When you plan a road lighting project, you might focus entirely on the brightness of the bulbs, but the physical hardware is just as vital. The poles, arms, and brackets you select form the lighting support system that determines whether your lights actually do their job. If you pick the wrong components, even the most expensive lamp will fail to provide the right coverage, leading to dark spots and dangerous glare. You must treat these structural elements as the foundation of your system because they dictate exactly where the light lands and how well it covers the pavement.

Structural stability is a major factor in how long your setup lasts and how safe it remains for the public. A pole that cannot handle wind or a bracket that lacks the strength to hold a heavy fixture creates a serious risk. Beyond durability, your hardware choices affect installation safety and the ease of future repairs. Planners look at these components to ensure the light is positioned at the perfect height and angle to help drivers see clearly. By choosing high-quality hardware that matches your specific road needs, you improve the load distribution and the lifespan of the system, making the streets much safer for everyone who uses them.

What role do poles, arms, and brackets play in street lighting systems

Poles, arms, and brackets are the essential structural components that define the physical architecture of a street light. The pole acts as the primary structural support, elevating the light to the necessary height to clear traffic and obstacles. While the pole provides the vertical lift, the arms are responsible for fixture positioning, extending the lamp out over the roadway to ensure the light is centered where it is needed most. Without these arms, light would often be wasted on sidewalks or shoulders rather than the driving lanes.

Brackets serve as the critical connection point, managing the load transfer from the heavy lighting fixture to the arm or pole. They are not just fasteners; they allow for precise alignment, ensuring the light hits the road at the correct angle. If any of these parts are mismatched, the entire system loses its effectiveness. When you select these components as a unified system, you ensure that the fixture stays steady under environmental stress, providing a reliable and safe environment for nighttime travel.

How do different street light pole shapes affect performance and use

The shape of a pole, known as its pole geometry, significantly influences both its structural strength and how it behaves in various environments. Straight poles are consistent in diameter from top to bottom, offering a classic look that is often used in parks or low-speed residential areas. However, tapered poles—which are wider at the base and narrow toward the top—are generally superior for high-stress environments. The tapered design allows for better weight distribution, making the pole more resilient against the constant vibrations of passing heavy traffic.

Planners must weigh the application suitability of these shapes against the specific needs of the project. For instance, square poles are often chosen for their aesthetic appeal in modern urban centers, but they may face higher wind resistance than round poles. Round, tapered poles are frequently the go-to choice for main thoroughfares because their aerodynamic shape reduces wind load. By understanding how the cross-section of a pole impacts its ability to stand firm, you can choose a design that balances visual appeal with the physical endurance required for long-term road use.

Why pole height is critical for light coverage and safety

Selecting the correct pole height is one of the most impactful decisions you will make for visual comfort and safety. The height of the pole determines the total coverage area on the ground; as you move the light higher, the beam spreads further, allowing for a more uniform glow across the pavement. If your poles are too short, the light is concentrated in small, intense pools that can create “hot spots,” making it difficult for a driver’s eyes to adjust to the surrounding darkness.

On the other hand, height must be balanced with the road type. On a multi-lane highway, taller poles are necessary to push light across several lanes without requiring a forest of poles. However, in residential areas, excessive height can cause light to spill into windows, creating a nuisance. Finding the “sweet spot” ensures that you maximize visibility while minimizing glare. When the height is matched perfectly to the road width, you create a seamless path of light that guides drivers safely without causing eye strain or light pollution.

How do arms and brackets control light reach and positioning

The arm length you choose is the primary tool for managing light projection across the width of the road. On roads where poles must be set back significantly from the curb for safety, a longer arm is required to reach over the driving lanes. This extension ensures that the center of the road receives the most intense illumination, which is vital for high-speed visibility. If the arm is too short, you risk leaving the middle of the road in a shadow, which is a major safety hazard.

Brackets further refine this fixture alignment by allowing for specific tilt and rotation. This precision is what helps you avoid dark spots in the lighting layout. If a bracket is not designed to hold the light at the correct angle, the beam may cut off too early or extend too far, wasting energy and reducing the effectiveness of the lighting plan. By coordinating the length of the arm with the adjustability of the bracket, you can place the light source exactly where the geometry of the road demands it.

When should single or double arm configurations be used

Choosing between a single arm or a double arm configuration depends heavily on the road width and the layout of your poles. Single-arm setups are the standard for most roadside installations, where the pole sits on the shoulder and lights one side of the street. This is a simple, cost-effective way to provide illumination for standard two-lane roads. It is a straightforward approach that handles standard loads without complex structural requirements.

Double-arm configurations are typically utilized when poles are placed in a central median. This allows a single pole to light both sides of a divided highway or a very wide boulevard simultaneously. While this reduces the total number of poles needed, it significantly increases the load distribution requirements. You must ensure the pole is strong enough to balance the weight of two fixtures and resist the torque caused by wind hitting two different directions. For planners, this choice is a balance between saving on pole costs and ensuring the structure can handle the doubled physical stress.

How do material choices impact pole strength and lifespan

The material strength of your poles and brackets is what determines their service life and how much maintenance they will require. Steel is the most common choice for heavy-duty applications because of its immense durability and lower initial cost. However, steel is prone to rust, meaning it requires high-quality galvanization or painting to survive in wet or coastal environments. If the corrosion resistance is not handled correctly, the structural integrity of a steel pole can degrade rapidly over a few decades.

Aluminum offers a lighter, more modern alternative. While it may not have the raw strength of steel, its natural resistance to oxidation makes it an excellent choice for salty air or humid climates. Aluminum poles are also easier to handle and install, which can lower labor costs. When you select a material, you are essentially choosing the maintenance schedule for the next 30 years. Steel provides the muscle for high-wind areas, while aluminum provides the longevity for corrosive environments, allowing you to match the hardware to the specific threats of your location.

Why wind load and foundation design cannot be ignored

Every street light pole acts like a giant sail, catching the wind and transferring that force down to the ground. Wind load is one of the most common causes of structural failure in lighting systems. If you use a large fixture or a very long arm without accounting for the wind pressure in your area, the pole can bend or even snap during a storm. This is why every selection must be backed by structural calculations that ensure the pole can withstand local peak wind speeds.

Foundation stability is equally critical because it is the anchor for the entire system. A pole is only as strong as the concrete base holding it. If the base is too shallow or the soil is too soft, the pole will lean over time, ruining your lighting alignment and creating a structural safety risk. Planners must ensure that the foundation is designed to handle the specific torque and weight of the chosen pole and arm configuration. Without a solid anchor, even the best-engineered pole is destined to fail.

What mistakes lead to premature failure of poles and brackets

Many design mistakes that lead to early failure happen during the planning phase. One frequent error is ignoring the total weight of the fixture and arm when selecting a pole. If the pole isn’t rated for that specific load, it will suffer from metal fatigue much faster than expected. Additionally, poor maintenance issues often stem from choosing hardware that is difficult to access or made of materials that cannot withstand local pollutants, leading to rapid rusting of brackets and bolts.

Structural failure can also occur if installation teams don’t properly level the pole or tighten the brackets to the manufacturer’s specifications. Vibrations from wind and heavy trucks can slowly loosen hardware that isn’t secured correctly, eventually leading to a fixture falling or an arm shifting out of place. Avoiding these mistakes requires a combination of accurate weight calculations, choosing weather-appropriate materials, and ensuring that the installation follows a strict quality control process to prevent the “slow drift” of hardware alignment.

What should be reviewed before finalizing street light pole and arm selection

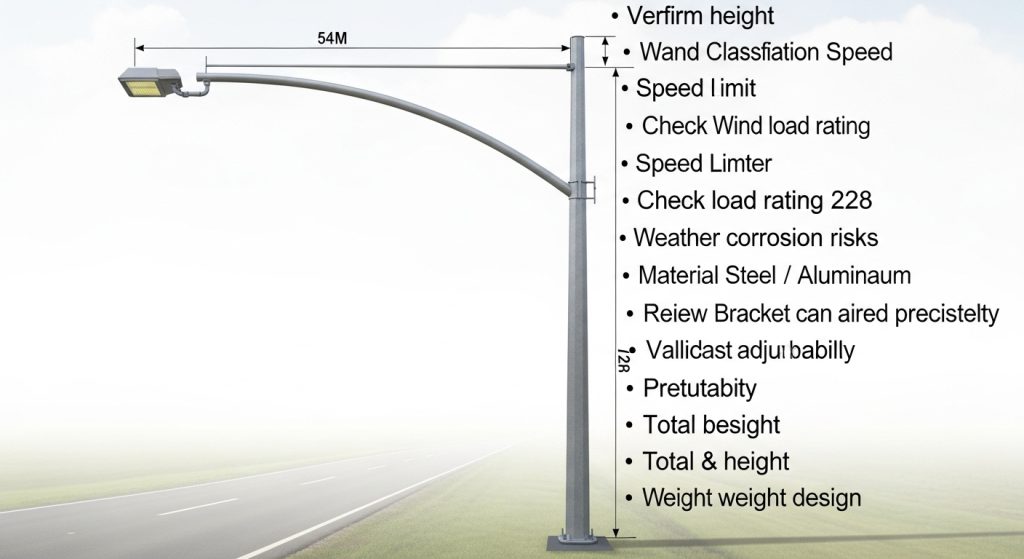

Before you commit to a purchase, you must perform a final design validation to ensure that all components work together as a system. You need to verify that the pole height and arm length will deliver the light exactly where the road layout requires. This is also the time to double-check that your hardware can survive the local climate, from high winds to salt spray. Achieving operational reliability starts with this thorough review process.

Use this selection checklist to ensure your hardware is ready for the road:

- Confirm the pole height is appropriate for the road classification and speed limit.

- Verify that the arm length provides enough overhang to reach the driving lanes.

- Check the wind load rating of the pole against local weather data.

- Ensure the material (steel or aluminum) matches the environmental corrosion risks.

- Review the bracket adjustability to confirm the light can be aimed precisely.

- Validate that the foundation design is sufficient for the total height and weight.

- Ensure the hardware allows for easy access during future maintenance cycles.

What are straight light poles and where are they commonly used

Straight light pole specs typically describe poles that maintain a uniform diameter across their entire length. These straight poles are most effective for urban roads, parking lots, and walkways where aesthetic consistency is a priority. Because they lack the natural load-distributing properties of tapered designs, they are usually found in areas with lower speed limits and less intense wind exposure. They offer a clean, vertical line that fits perfectly into modern cityscapes and pedestrian-friendly zones.

Why are polygon light poles preferred for highways

Polygon light pole highways are a staple in major infrastructure projects because their multi-sided shape provides superior resistance to bending. These polygon poles are specifically engineered for highway lighting where they must stand tall against the high-velocity air displaced by speeding trucks. The flat surfaces of the polygon shape actually help the pole resist twisting forces better than a standard round pole, making them the most reliable choice for heavy-duty, high-speed corridors.

What benefits do foldable light poles offer for maintenance and safety

When you look at Foldable light pole benefits, the primary advantage is the ease of maintenance access. These poles can be lowered to ground level, which eliminates the need for expensive bucket trucks and improves safety design for technicians. They are particularly useful in areas where a truck cannot easily reach, such as narrow park paths or steep embankments. By allowing the hardware to be serviced at eye level, you reduce the risks associated with working at heights.

What are lighting pole arms and brackets and how are they selected

A Lighting pole arm bracket is the specialized hardware that secures the light to the structure. Arm brackets are selected based on the specific fixture mounting requirements of the lamp. You must choose a bracket that not only fits the diameter of the arm but also allows for the necessary degree of tilt. Selecting the right bracket is what ensures your light stays pointed at the road rather than shifting due to vibration or wind over time.

How should planners determine the correct street light pole height

Effective Street light pole height guide strategies revolve around coverage design. Planners use pole height planning to ensure that the light from one pole reaches the “pool” of light from the next. The higher the pole, the further apart they can be spaced, which can save on project costs. However, this must be balanced with the power of the lamp to ensure the light is still bright enough when it finally reaches the road surface.

How do aluminum and steel light poles compare in real applications

The Aluminum vs steel light poles debate often comes down to weight and rust. Aluminum poles are highly valued for their light weight and natural resistance to sea salt, making them perfect for coastal cities. Steel poles, however, offer the high-tension strength needed for incredibly tall installations or areas with extreme wind. In real-world applications, planners often choose steel for its raw power and aluminum for its low-maintenance longevity.

What does a tapered light pole design achieve structurally

The Tapered light pole explained focuses on load efficiency. A tapered design works by placing more material at the base where the stress is highest and less at the top where the weight is lower. This shape naturally dampens vibrations and resists the “pendulum effect” caused by wind hitting the light fixture. It is a highly efficient way to build a pole that is both strong and relatively light, making it the standard for modern roadway engineering.

How is wind load calculated for street light poles

A Light pole wind load calculation involves determining the wind pressure exerted on the surface area of both the pole and the light fixture. This structural calculation is vital to ensure the pole doesn’t buckle under pressure. Engineers look at the “EPA” (Effective Projected Area) of the light fixture and the arm to determine how much force will be transferred to the pole, ensuring the entire assembly is safe for the local wind zone.

When should single or double arm brackets be used

Single vs double arm bracket decisions are based on the roadway layout. A single arm is perfect for standard roadside poles, while a double arm is the preferred choice for median-mounted poles that need to light two directions at once. Using a double-arm bracket on a single median pole is a smart way to maximize the utility of the hardware while maintaining a clean, symmetrical look for the highway.

Why is a proper street light pole foundation essential for long-term stability

The Street light pole foundation is what provides the ultimate structural stability. Without a correctly engineered foundation design, the pole is susceptible to leaning or shifting as the soil changes with the seasons. A solid concrete base ensures that the pole stays vertical and the light stays aimed correctly for decades. It is the most critical part of the installation because once it is poured, it is the hardest part to fix or replace.

Final Thought

When you treat street light poles, arms, and brackets as an integral part of your lighting design rather than an afterthought, you create a road environment that is safer, more durable, and cost-effective. The physical structure is what translates your lumen and wattage plans into actual visibility on the pavement. By prioritizing the right mounting geometry and structural stability, you ensure that your community benefits from clear, uniform light that stands the test of time.

- 10 Meters Lamp Post

- 10 Meters Pole

- 1000w Led Projector

- 100W LED Tunnel Light

- 12 Meters Lamp Post

- 12 Meters Pole

- 1200w Led Projector

- 15 Light Pole

- 1500w Led Projector

- 150W LED Tunnel Light

- 1800w Led Projector

- 2 In 1 Solar Flood Light

- 200w Led Tunnel Light

- 50w Led Tunnel Light

- 6 Meters Lamp Post

- 6 Meters Pole

- 8 Meters Lamp Post

- 8 Meters Pole

- 800w Led Projector

- 80w Led Tunnel Light

- Colourful Decorative Light

- Conical post

- Courtyard Lamp

- courtyard light

- courtyard lighting fixture

- Decorative Landscape Light

- Decorative road Light

- Flood Light For Courtyard

- Flood Light for Garden

- Flood Light For Outdoor

- Foot Led High Bay Lights

- high bay led lights 100w

- industrial lampshade

- industrial LED shed lights

- industrial magnifying glass with light

- Integrated Solar Flood Light

- led courtyard lamp

- led courtyard light

- led high bay light 100w

- LED Projector For Stadium

- Led UFO High Bay 150W 5000k

- Lighting Plants Mining Price

- Maintenance Free LED Street Light

- Pic Controlling Tunnel Light

- PLC controlling tunnel light

- Post Top Garden Light

- RGB Landscape Light

- Rgbw Decorative Light

- Smart Tunnel Light

- solar courtyard lamp

- solar courtyard light

- Solar LED Road Light

- Solar Street Light For 10 Meter Pole

- Solar Street Light For 12 Meter Pole

- Solar Street Light For 6 Meter Pole

- Solar Street Light For 8 Meter Pole

- Split Type Solar Flood Light

- Sporting Projector

- Stadium Led Projector

- Street Lighting Post

FACEBOOK

FACEBOOK

TWITTER

TWITTER

LINKEDIN

LINKEDIN